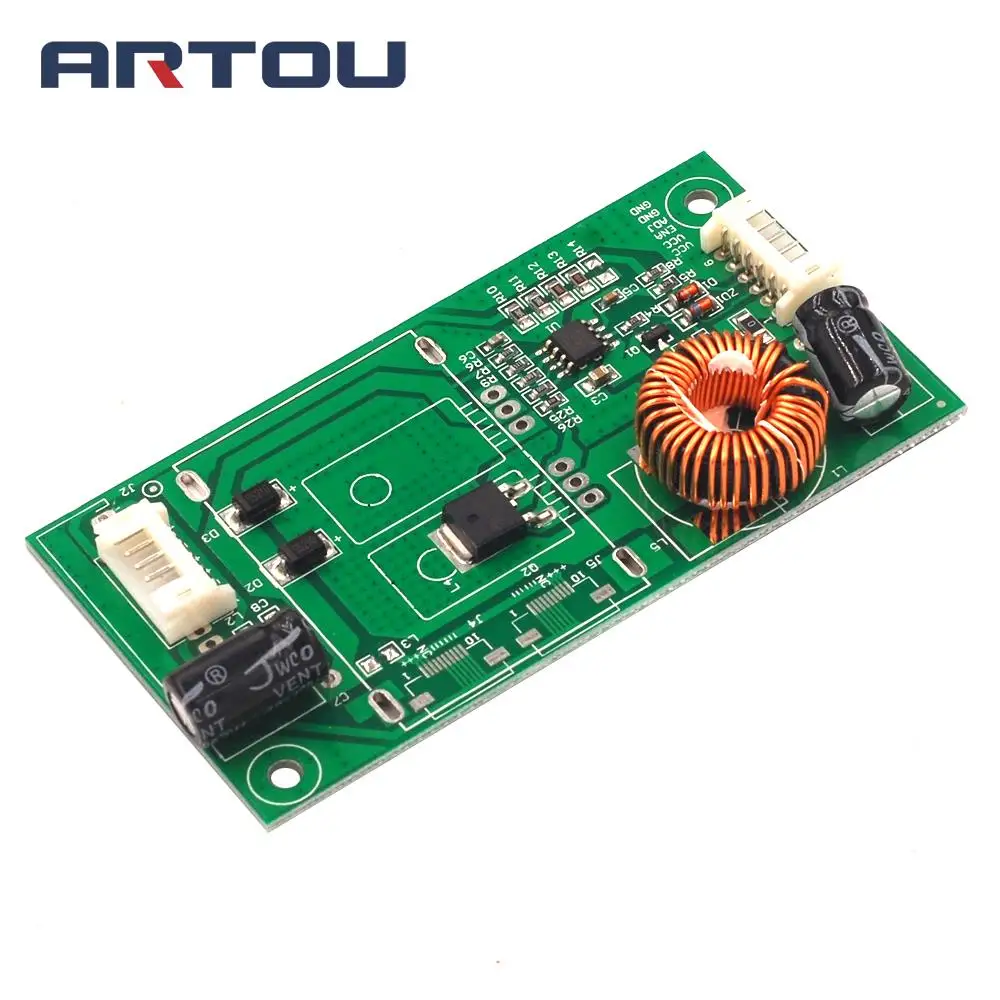

TV Backlight Driver Module LED Constant Current Inverter CA-255 10-42Inch LED Display Adaptive Power Supply Board For LED TV

- I am an international seller

Our shop sells the most popular 3C consumer electronics products,such as mobile phone accessories,computer accessories,game peripherals,smart wearables,and follow the most popular fashion trends. If you like our products,please follow us,become our follower and fan.We will provide you with the most popular products to satisfy your fashion shopping experience.Package : SOPis_customized : YesModel Number : CA-255Application : ComputerCondition : NewType : Voltage RegulatorBrand Name : ARTOU

The common electronic symbol e of the backlight board is as follows:

A.VCC: power supply voltage positive, circuit supply voltage (voltage is usually 12V or 24V)

B.ON/OFF, ON, EN, ON_BL, etc.: switch pin, switch signal pin (voltage range is usually between 2.5V-5V)

C.PWM, PDIM, VDAJ, BL-PWM, etc.: brightness adjustment feet or dimming feet. (Dimming will have two modes, one is digital mode-PWM, the other is analog dimming-DC. PWM is called pulse width adjustment, it produces a rectangular square wave signal, the frequency is generally 200HZ-2KHZ, voltage The amplitude is usually 3.3V, PDIM is short for English, and Dim is dark. The meaning of the word is “brightness.” Analog dimming is performed by DC voltage, usually by directly supplying 0V-5V DC voltage to the pin. The purpose of brightness.)

GND: ground (power supply negative)

LED+: LED (light bar) positive

LED-: LED (light bar) negative

The above symbols contain most of the commonly used es on the LCD motherboard and the backlight board. It is not wrong to connect them according to their respective es.

Frequently asked questions before purchase:

Question 1: Can a constant-current driver board of a certain size TV be used instead?

A: As long as the working voltage of the light bar is below 80V, no matter how many inches of TV, this product can light it. Note: What is said here is just lighting, not to say that it is suitable. If you need the exact answer, the best way is to provide the backlight module of the panel (the working voltage of the light bar, rated current, etc.). If you can provide accurate data, we can do a "private customized" service.

Then again, what if you can't determine how many volts the light bar is? At this time, there is a very simple way to find the constant current driver board on the machine to see the output voltage of the output filter electrolytic capacitor is how many volts? If it is 100V withstand voltage, it means that its light bar voltage will not exceed 80V, then my product can be spotted, and it can be taken decisively.

One thing to note after knowing that the voltage can be lit up is that it is about current. The size of the LED lamp bead determines the rated current required, but for various reasons, the module factory will use a variety of different specifications of the lamp to produce a variety of rated operating current. In order to solve this problem, we all recommend using our standard for models above 26 inches: constant current 480 mA, if it is 24 inches or less, the current is reduced to half, 240 mA. Here we have to explain the real problem: 480MA is not a suitable screen for 26 inches or more, just choose the approximate value for the case where the exact cannot be determined. According to the data returned by many users before, it is suitable to use this current, but occasionally too bright, etc., the easiest way is to solve the problem by dimming the function foot, connect the dimming foot After Vadj, the brightness is dimmed.

The following is a description of the product features:

Uses: 10-42" LED TV backlight boost board.

Product features: Made in Taiwan imported program, BOOST structure, conversion efficiency of more than 92%, low heat generation, stable product, longer service life, small PCB size, ultra-thin design, to meet the most demanding requirements, accurate The current control error is within ±5%, and the flexible and convenient current adjustment design can be easily changed to match the screens of different manufacturers and models. Designed to meet EMC requirements and CE certified. High reliability, one year warranty! You can use 12V power supply to reduce system cost!

This product is a constant current board. The focus of the work is constant current. The voltage is automatically adapted. The voltage of the backlight module is automatically adjusted. For example, when the backlight module is 4 and 20 strings, the voltage is adjusted to 3.2V*20. String = 64V or so, assuming that each string of LED current is 60MA, then you only need to set the current to 240MA to click on this screen.

It is made of iron-silicon-aluminum magnetic ring inductor, higher temperature coefficient, higher magnetic saturation and higher stability. Due to the extremely high conversion efficiency of the system, the heat generation of the device is very low, and the temperature rise is controlled at around 25 °C (Note: temperature rise = device surface temperature - ambient temperature). When the temperature is 25 °C, the surface temperature of the component is up to 50 °C (working conditions: Input 24V, output 64V480MA.)

Limit :

At 24V input: Vout=75V Iout=720mA or up to 60W

At 12V input: Vout=75V Iout=400mA or up to 30W

The limit parameter refers to the maximum bearing capacity of the product in the application process. In actual use, please use it below the limit parameter to ensure the reliability of the product.

Questions about installation

Question 1: Can't you brighten it?

1. Check if the polarity of the cable is correct? Is the LED positive and negative polarity correct?

2. Measure the power supply voltage to see if there is any voltage on the board. When the machine is turned on, measure the LED+ with or without boost. Generally, it will be higher than the VCC voltage.

3. If there is no boost, please measure whether there is voltage on the ON pin. The normal voltage should be about 3.3V.

4. If the above conditions are normal, then measure the resistance value of the series connection between LED-to GND in the case of power-off and shutdown. Normally, it should be a small resistance value, less than 2 ohms.

After all the above steps are verified, all that remains is that there may be only a problem with the LED strip.

Question 2: The machine is on, but the brightness is not enough?

First, adjust the brightness to the brightest by remote control. If it is still not bright enough, measure the PDIM pin again. If the voltage is always higher than 4V through the adjustment, you need to change the voltage by other means, and then directly test the foot. If you can satisfy the brightness, you can achieve the brightness requirement by changing the voltage of the pin.

If the brightness is not enough by breaking the foot, you need to increase the brightness by other means.

/product/40/7765712/1.jpg?9209)